www.aero-defence.tech

02

'24

Written on Modified on

Fives News

FIVES: ADDUP AND AIRBUS DELIVER THE FIRST METAL 3D PRINTER TO ESA

The Metal 3D Printer was successfully launched by NASA Mission NG-20 towards the International Space Station.

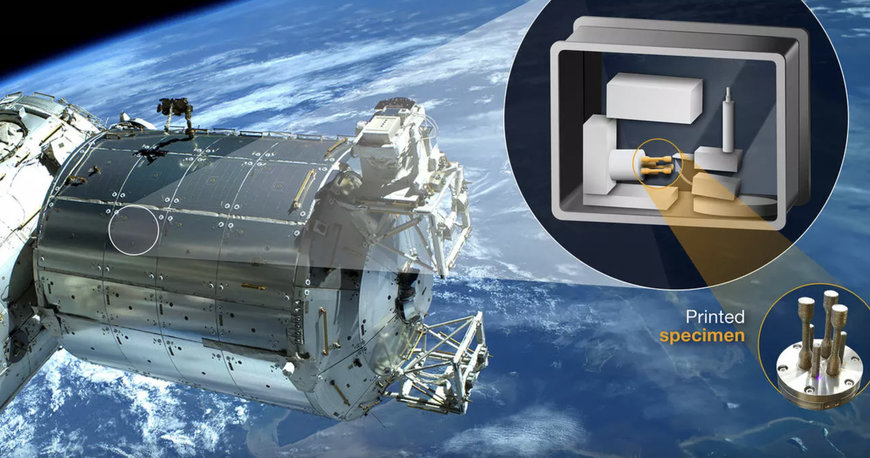

View of the 3D printed specimen in the ISS. Illustration courtesy of AIRBUS.

AddUp (joint venture created by Michelin and Fives), a global metal additive manufacturing OEM, and Airbus Defence & Space, have delivered the first metal 3D printer to the European Space Agency.

This metal 3D printer was developed by an industrial team led by Airbus Defence and Space under a contract with the European Space Agency (ESA), co-funded by Airbus Defence and Space. The metal 3D printer was designed to evaluate the capabilities and performance of additive technology and to perform metal disposition in 3D under sustained microgravity conditions.

The ability to manufacture spare parts directly in space, without having to transport them from Earth, marks a new stage to propel the next generation of space exploration. Not only will this generate millions in savings, it will also pave the way for human spaceflight by making their autonomous operation viable.

Metal3D Project

The "Metal3D" project began in 2016 when the European Space Agency awarded the contract to Airbus Defence & Space. A key objective: To create the first metal 3D printer to safely operate under microgravity, aboard the International Space Station. AddUp, a leader in metal 3D printing, has been supporting the Airbus group for over 10 years, not only with the supply of flight parts, but also on a variety of innovation projects.

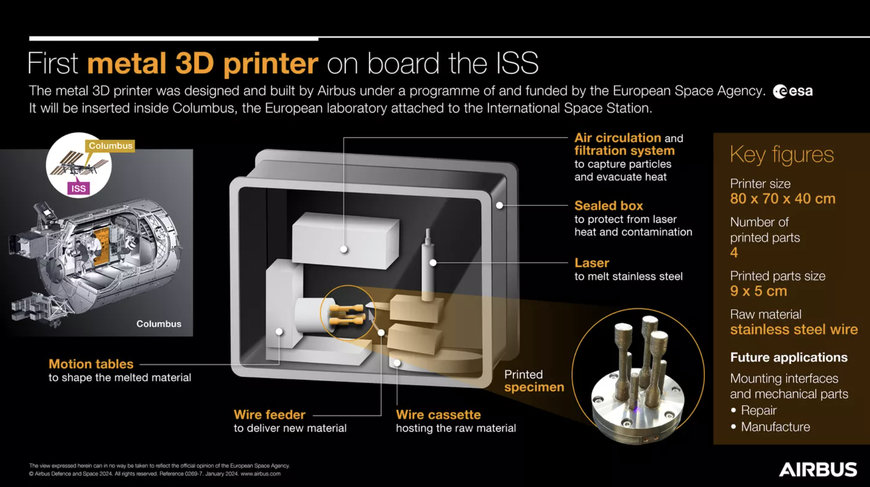

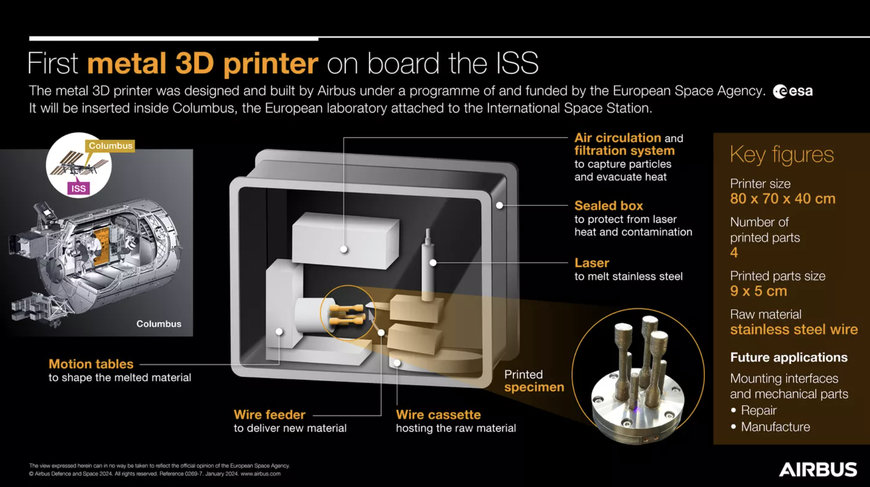

Metal 3D Printer explanation. illustration courtesy of AIRBUS.

An Innovation Marking a New Stage in Space Exploration

The metal 3D printer will be installed in the ISS in early 2024, on board the Columbus European Science Module, alongside the other experiments carried out by European teams. Four specimen are planned to be printed by the metal 3D printer in the Columbus module and for reference and comparison, these specimen will also be printed on ground. The specimens will be returned to Earth, analyzed and compared with those produced on the ground. The aim of these experiments is to make extraterrestrial metal 3D printing viable, for example, for the manufacture of spare parts. Metal 3D printing in space would limit the logistics needs from Earth, which can take up to 12 months between preparation, take-off and delivery.

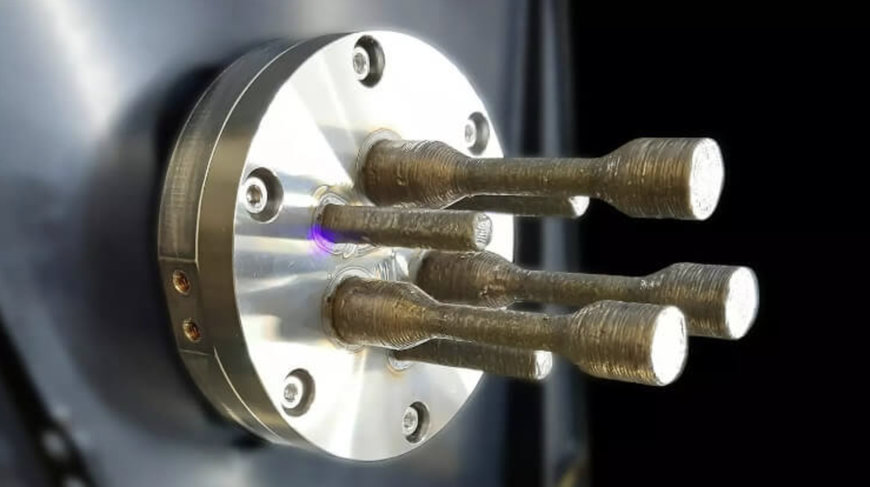

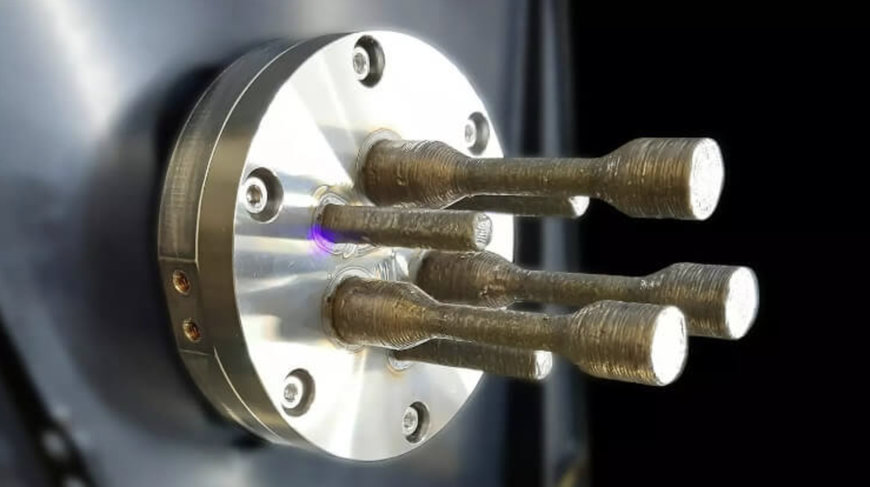

Samples produced by the Metal 3D Printer prior to launch to the space station. Photo courtesy of ESA.

AddUp (joint venture created by Michelin and Fives), a global metal additive manufacturing OEM, and Airbus Defence & Space, have delivered the first metal 3D printer to the European Space Agency.

This metal 3D printer was developed by an industrial team led by Airbus Defence and Space under a contract with the European Space Agency (ESA), co-funded by Airbus Defence and Space. The metal 3D printer was designed to evaluate the capabilities and performance of additive technology and to perform metal disposition in 3D under sustained microgravity conditions.

The ability to manufacture spare parts directly in space, without having to transport them from Earth, marks a new stage to propel the next generation of space exploration. Not only will this generate millions in savings, it will also pave the way for human spaceflight by making their autonomous operation viable.

Metal3D Project

The "Metal3D" project began in 2016 when the European Space Agency awarded the contract to Airbus Defence & Space. A key objective: To create the first metal 3D printer to safely operate under microgravity, aboard the International Space Station. AddUp, a leader in metal 3D printing, has been supporting the Airbus group for over 10 years, not only with the supply of flight parts, but also on a variety of innovation projects.

Metal 3D Printer explanation. illustration courtesy of AIRBUS.

An Innovation Marking a New Stage in Space Exploration

The metal 3D printer will be installed in the ISS in early 2024, on board the Columbus European Science Module, alongside the other experiments carried out by European teams. Four specimen are planned to be printed by the metal 3D printer in the Columbus module and for reference and comparison, these specimen will also be printed on ground. The specimens will be returned to Earth, analyzed and compared with those produced on the ground. The aim of these experiments is to make extraterrestrial metal 3D printing viable, for example, for the manufacture of spare parts. Metal 3D printing in space would limit the logistics needs from Earth, which can take up to 12 months between preparation, take-off and delivery.

Samples produced by the Metal 3D Printer prior to launch to the space station. Photo courtesy of ESA.

www.fivesgroup.com